DuFu (Shanghai) Industrial Co., Ltd

5052 Aluminum Coil

5052 Aluminum Coil

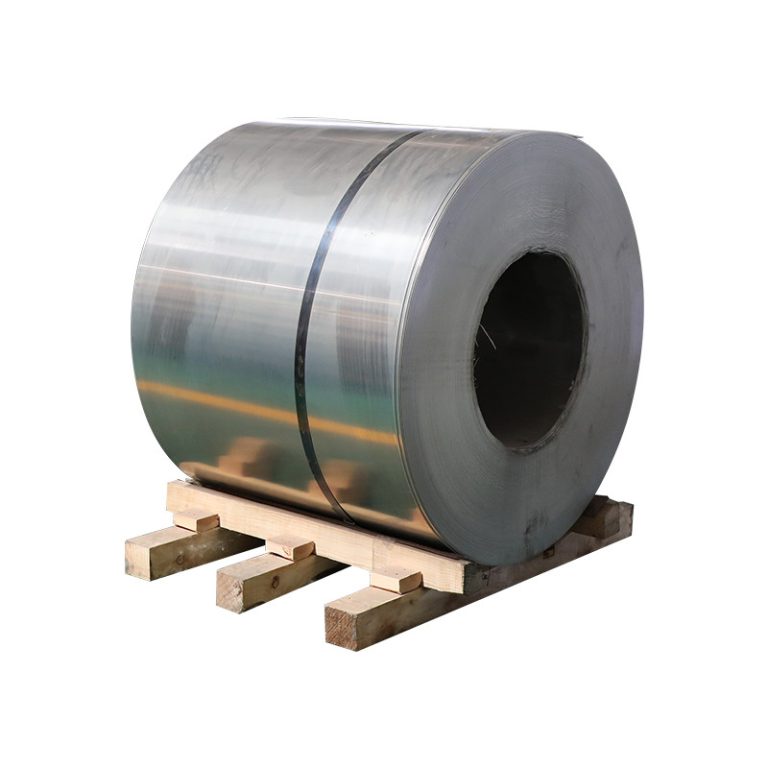

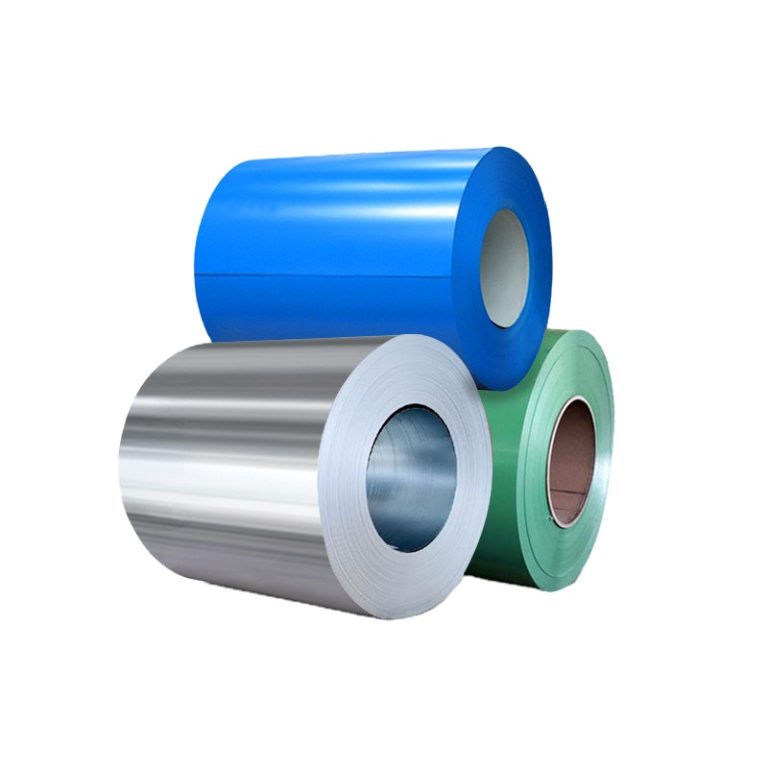

- Thickness: 0.12-1.5mm

- Width: 600-1250mm

- Coating Mass: 4-38 μm

- Surface Treatment: PVDF/ PE/ EOXY/ PU

- Certificate: ISO 9001

Description

Temper: H32, H24, H22, H112, O

Thickness: 0.2mm-6mm

Width: 500/1250/1500/2000/2200mm

Length: 2500/3000/4000/6000/8000mm

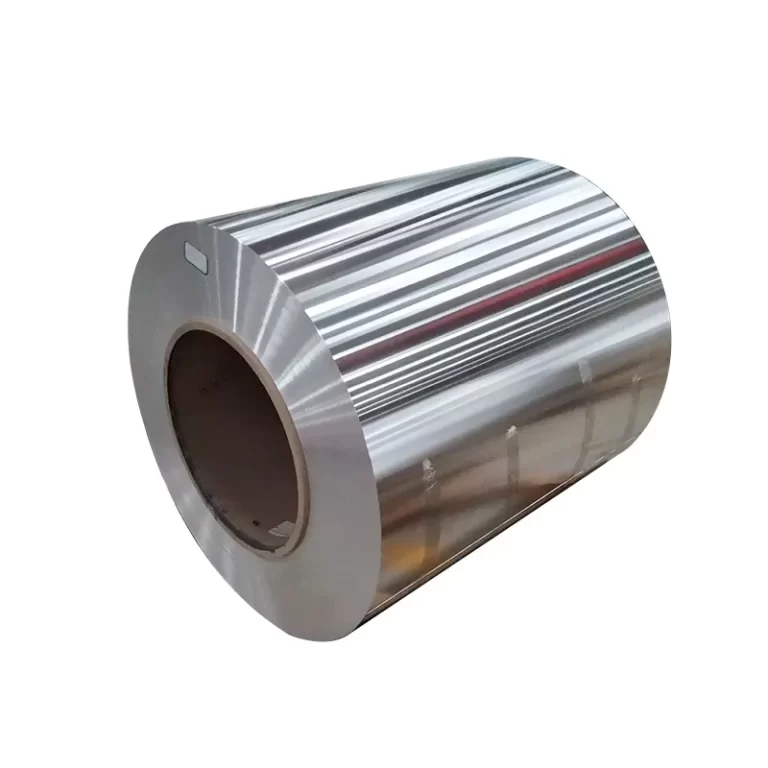

Surface: mill finish surface, bright, polished surface, with blue PVC films or paper-interleaved

5052 Aluminum Coil is an alloy grade under the Standard Specification for Aluminum and Aluminum – Alloy Sheet and Plate 1 on B 209 – 06 designation. It is a highly versatile alloy with excellent fatigue strength and weldability.

5052 aluminum alloy coil contains 2.5 percent magnesium and 0.25 percent chromium. Its lightweight and corrosion-resistant properties make it suitable for the marine environment, aircraft fuel tanks, architecture, manufacturing, and more.

What does 5052 mean in aluminum coil?

Each alloy grade has a four-digit number, such as 5052. The first number represents the grade’s main alloying element or the series it belongs.

The second number is usually a zero. If not, it represents the alloy variation. The third and last numbers represent the specific alloys in the series. Today’s major alloying elements include silicon, iron, copper, manganese, and magnesium.

5052 aluminum coil belongs to the 5000 grade. It starts with the number 5 because its central alloying element is Magnesium. Sometimes, they also alloy manganese with magnesium in the 5000 series.

The last two digits, 52, represent the grade in the 5000-grade category. These digits differentiate them from the other alloy grades, such as 5059, 5083, 5086, and more.

Hence, 5052 in aluminum coil means that the aluminum coil is alloyed with magnesium and belongs to the 5000 series.

Properties of 5052 alloy aluminum coil

5052 aluminum coil is a popular alloy grade because of its versatility. The alloyed magnesium gives good aluminum weldability, higher fatigue strength, and corrosion resistance.

The grade offers excellent resistance against saltwater corrosion, making it perfect for the marine environment. It also has commendable fatigue strength with a limit of 115 MPa in the H32 tempers and 123 MPa in the H34 tempers. With superb versatility, it has become one of the most widely utilized non-heat-treatable aluminum alloys in everyday use.

What is the difference between 5052 H32 and 5052 H34?

5052 H32 and 5052 H34 have the same alloy composition. Hence, they are variants of the same material. They are the most widely used 5052 aluminum plate. However, they have different mechanical properties.

The H3 portion denotes the incomplete annealing and hardening of the aluminum sheet. The aluminum sheet needs stabilization to avoid it becoming too soft. The next digit then indicates the hardness grade. As the number increases, so do the hardness level and grade.

5052-H32 Aluminum is a quarter-hard temper, while 5052-H34 Aluminum is a half-hard temper. Another hardness grade is “6”, which stands for 3/4 hardness, and “8”, which stands for full hardness.

Application

Coated aluminum coil and sheet are used in Roofing System and Ceiling Decoration for Airport, Railway Stations, Exhibition Halls, Factory and Stadium

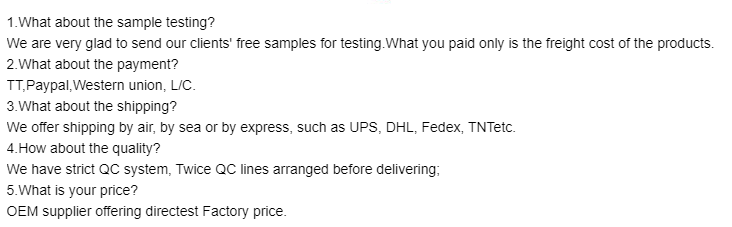

FAQs

Not matter where you come from, give us a call, we will pick up from the airport, station, etc.

Welcome take a visiting to our company!

Of course, why not?

We have 6 sales team, total 30+ sales.

We are 20+ years, from last century.

Expanding the market, and cultivate our techniques, two ways all in work together.

here, following is our working plant, all is same when you come to China to audit.

you can check the HS code on this website http://www.hsbianma.com/

if you could not make sure, you can contact with us.

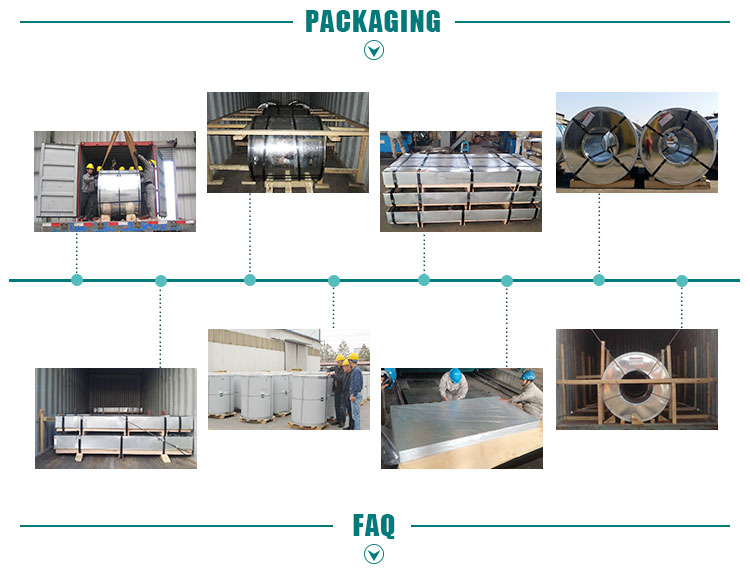

Present we most use the FOB, CFR, CIF.

Other kind also available, such as DDU, DDP.

From Shanghai.

If you specified the department port, no problem such as NingBo, Guangzhou, Shenzhen, QingDao.

T/T, L/C, Cash, Cheque.

In stock item delivery out by 1-5 days.

Custom producing order, usually 5-15 days.