DuFu (Shanghai) Industrial Co., Ltd

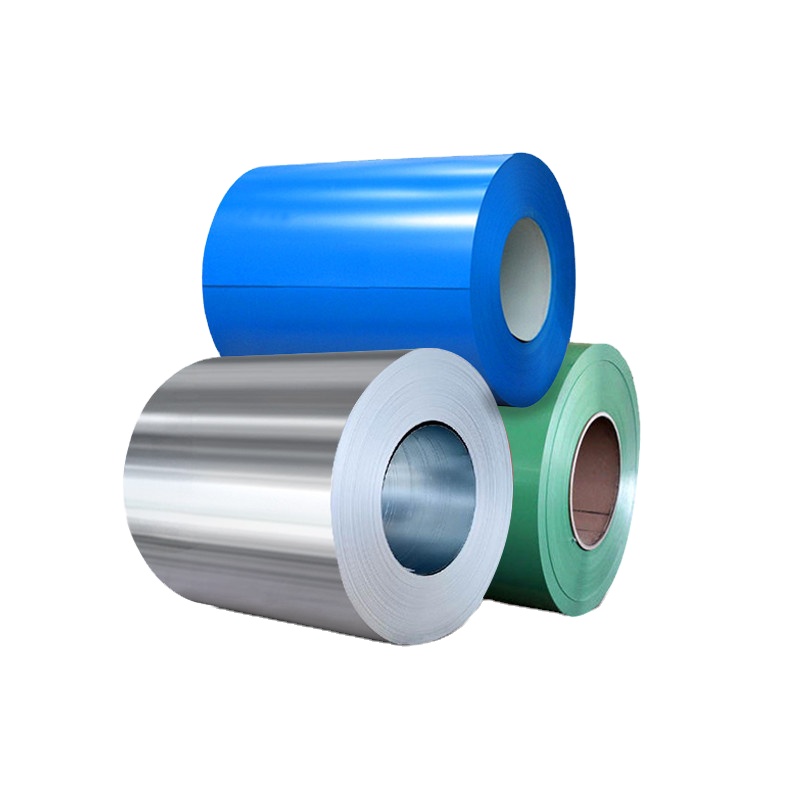

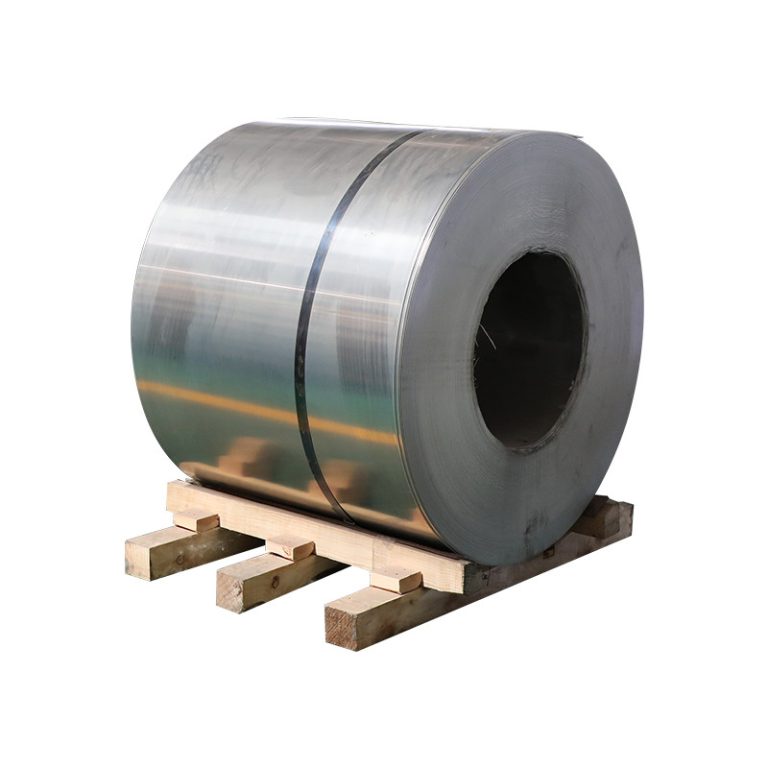

1060 Aluminum Coil

1060 Aluminum Coil

- Thickness: 0.2-1.5mm

- Width: 600-1250mm

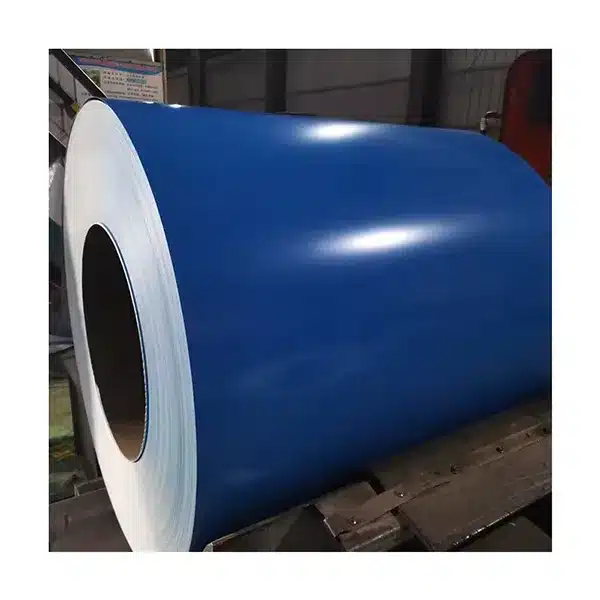

- Coating Mass: 4-38 Um

- Surface Treatment: PVDF/ PE/ EOXY/ PU

- Certificate: ISO 9001

Description

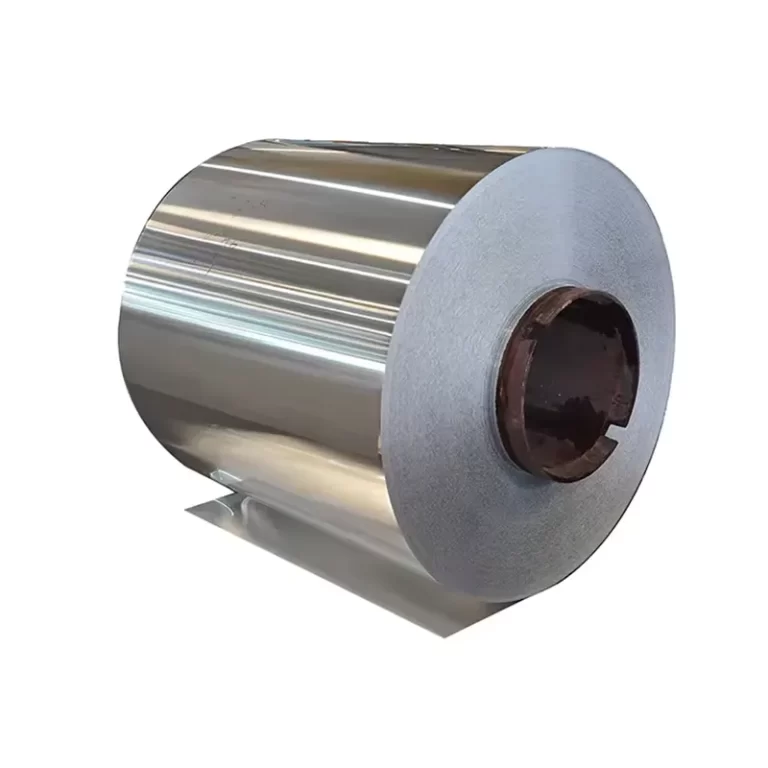

Temper: O, H12, H14, H16, H24, H26, H18

Thickness: 0.2mm to 10mm

Width: 100mm to 2600mm

| Alloy | Silicon | Iron | Copper | Manganese | Magnesium | Chromium | Zinc | Titanium | Other Elements | Aluminum | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | … | 0.05 | 0.03 | Each | Total | |

| 0.03 | … | 99.6 min | |||||||||

1060 aluminum is a very popular alloy in the aerospace, automotive, and construction industries. This alloy is known for its formability and corrosion resistance, making it an excellent choice for applications where strength and impact resistance are essential.

Properties of 1060 alloy aluminum coil

1060 alloy aluminum has high corrosion resistance and good formability. Thus, it is commonly used to build chemical equipment and railroad tank cars. It can be formed through hot or cold works using commercial techniques.

Its chemical composition limits are as follows:

- Silicon – 0.25

- Iron – 0.35

- Copper – 0.05

- Manganese – 0.03

- Magnesium – 0.03

- Zinc – 0.05

- Titanium – 0.03

- Aluminum – 99.60

Its physical data is as follows:

- Density – 0.0975 lb/cu.in.

- Melting point – 1200 degrees Fahrenheit

- Specific gravity – 2.705

This alloy is excellent for outdoor use in high humidity or salt spray exposure conditions. Its machining characteristics are better in harder tempers compared to soft tempering conditions. It can be welded through standard commercial methods.

1060 Aluminum Coil vs. 1050 Aluminum Coil

The 1050 and 1060 are the most widely used aluminum in the market, and both are from the 1xxx series industrial pure aluminum. However, they have slightly different characteristics and are used for various purposes.

The properties of the aluminum 1060 alloy are similar to the 1050 alloy, but 1050 has copper added to it for better molding and weldability. 1060 is 99.6% pure aluminum for higher tensile strength and high formability. 1060 has higher electrical conductivity (55% of copper) than the 1050 alloy.

The main application of 1060 alloy is for decorative materials, such as window frames and door frames; it is also used for welding rods and other electrical conductors. 1050 is often used in kitchen utensils, reflective appliances, discs, and clock surfaces.

Application

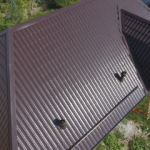

Coated aluminum coil and sheet are used in Roofing System and Ceiling Decoration for Airport, Railway Stations, Exhibition Halls, Factory and Stadium

FAQs

Not matter where you come from, give us a call, we will pick up from the airport, station, etc.

Welcome take a visiting to our company!

Of course, why not?

We have 6 sales team, total 30+ sales.

We are 20+ years, from last century.

Expanding the market, and cultivate our techniques, two ways all in work together.

here, following is our working plant, all is same when you come to China to audit.

you can check the HS code on this website http://www.hsbianma.com/

if you could not make sure, you can contact with us.

Present we most use the FOB, CFR, CIF.

Other kind also available, such as DDU, DDP.

From Shanghai.

If you specified the department port, no problem such as NingBo, Guangzhou, Shenzhen, QingDao.

T/T, L/C, Cash, Cheque.

In stock item delivery out by 1-5 days.

Custom producing order, usually 5-15 days.